electrical center b2c

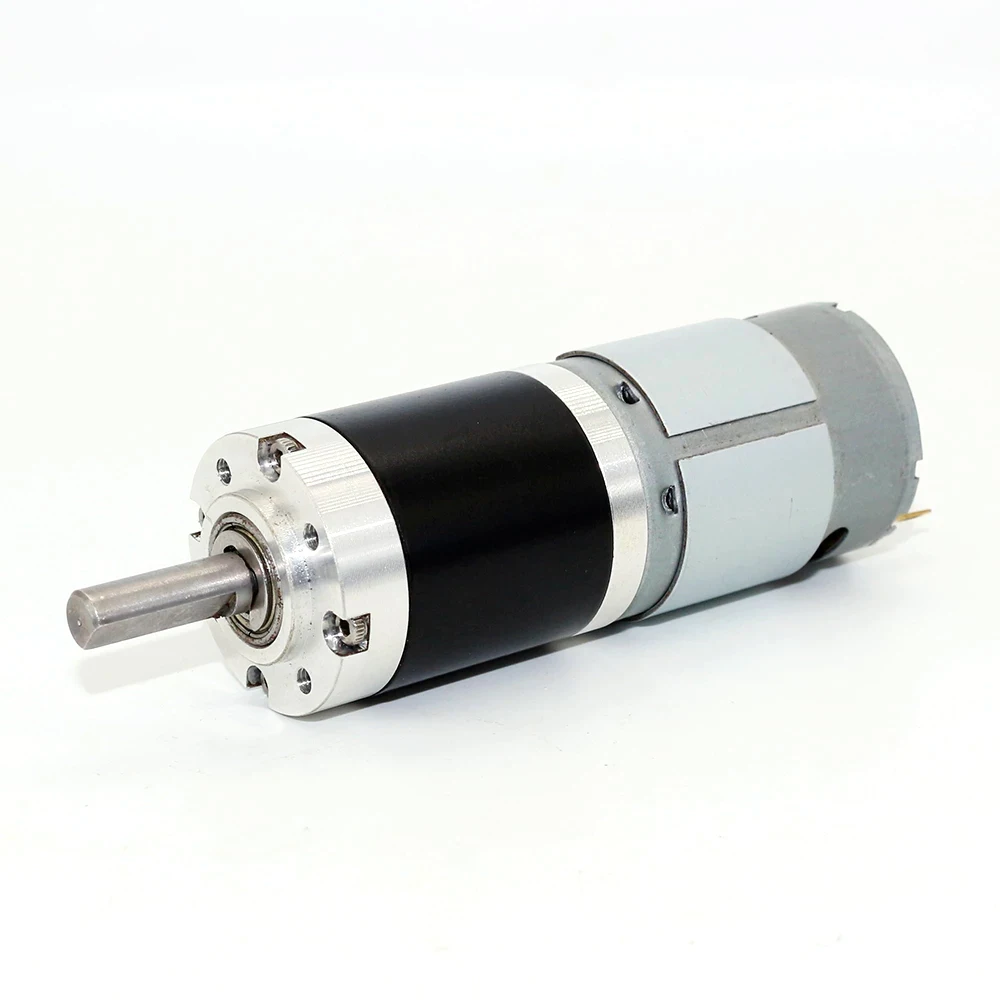

28GP-385 Planetary DC Gear Motor 12V 24V Adjustable Speed Can Be Reversed High Torque Low Speed Small Motor Electric High Life

Couldn't load pickup availability

SPECIFICATIONS

28GP-385 Planetary DC Gear Motor 12V 24V Adjustable Speed Can Be Reversed High Torque Low Speed Small Motor Electric High Life

Brand Name: HYSMOTOR

Certification: ROHS

Origin: Mainland China

Continuous Current(A): 0.1A

Output Power: 5W

Commutation: Brush

Type: Gear Motor

Protect Feature: Explosion-proof

Construction: Permanent Magnet

Usage: BoAt

Usage: car

Usage: Electric Bicycle

Usage: Fan

Usage: Home Appliance

Efficiency: IE 1

Model Number: 28-385

Torque: 30kg.cm

The following is a detailed description of the motor

(1) Name of the motor: 12V 24V Planetary dc geared motor

(2) What is a planetary geared motor?

Planetary geared motor is a new type of geared motor with wide versatility.

The motor has small size, low noise, large output torque, stable operation and long life.

The Life of the planetary gear motor is 3 times the ordinary gear motor (But the premise is that the load of your project does not exceed the torque of the motor)

(3) Rated voltage : DC 12V Or DC 24V

(4) No load speed have :

12 / 16 / 25 / 53 / 64 / 80 / 125 / 320 / 500 / 1600 RPM / Min

(5) About the rated load torque of the motor: the no-load speed of the motor is different, the torque will also be different, the lower the speed you choose this motor, the greater the torque of the motor;

In short, the slower the motor spins, the heavier the load it can drive, and the faster the motor spins, the lighter the load it can drive.

Some people will have a doubt. If the maximum speed of this motor is purchased, such as 1600rpm, if we reduce the speed of the motor from 1600rpm to 12rpm, when the motor is running at 12rpm, can the torque of the motor reach 45KG?

This is impossible. When the speed of the motor is adjusted, the torque of the motor will also decrease as the speed decreases. For example, the speed of the motor you bought is 1600rpm, and the torque of the motor is 0.8KG.CM. When you reduce the speed of the motor, the torque of the motor will be lower than 0.8KG. If the speed of the motor is greatly reduced, the torque of the motor will also be greatly reduced.

If you buy the lowest speed of this motor, such as 12rpm, the torque of the motor is 45KG, if you reduce the speed of the motor from 12rpm to 1rpm, the torque of the motor will also be lower than 45KG.

So you need to consider whether the final torque of the motor can reach the load of your project after the motor is decelerated. If not, you need to consider choosing other lower speeds or other motors.

You can contact us about the principle of torque change with speed, we can help you avoid buying mistakes, thanks!

(6) Direction of rotation of the motor: CW Or CCW ; Support Reversed

(7) Gear material: Metal gears make the motor last longer

(8) The speed of the motor can be adjusted using the speed controller. If you also need a speed controller, you can contact us and we will recommend the most suitable controller for you.

For example, the speed of the motor is 12rpm, you can adjust speed from 0rpm to 12rpm or 12rpm to 0rpm through the speed controller,that is, the speed you choose to buy is the adjustable range Maximum speed.

However, if you use a speed controller to control the rotation speed of the motor, the torque of the motor will decrease as the speed decreases. If the torque of the motor is lower than the load of your project, the motor will be damaged, you need to pay special attention.

(9) This motor is suitable for a variety of micro-automation equipment. As long as you confirm that the motor voltage and torque of your choice are suitable for the voltage and load of your project before purchase, there is no limit to the scope of use of this motor.

For example, Smart Robot ; Smart Door Lock ; DIY tank etc.

The following is a description of the quality materials and structures of this motor.

① D-type output shaft

② Planetary gear

③ Gear carrier

④ Positioning spacer

⑤ Gear outer wall

⑥ Sun gear

⑦ Connection plate

⑧ High-speed motor

⑨ 4 M3 screw holes

⑩ Double ball bearing

(A) Metal planetary gear

(B) Double ball bearing

(C) Pure copper coil

(D) Thickened motor carbon brush

(E) Efficient and stable operation

(F) Low noise 50dB

(G) Easy and firm installation

(H) Support non-standard customization

Refer to the following diagram to simply calculate the torque required for your project, that is, the torque of the motor you should choose.

The following are Figures A and B, respectively

The radius of Figure A is 1CM, which means that the radius of the object driven by the motor is 1CM, and the weight of the object is 10KG, then the motor torque you need to choose is 10KG.CM;

The radius of Figure B is 10CM, which means that the radius of the object driven by the motor is 10CM, and the weight of the object is 10KG, then the motor torque you need to choose is 100KG.CM;

Simply put, the load of your project needs to be inferred from the radius of the object, not just the weight of the object.

It is calculated as follows

Calculate the required torque = the radius of the driven object CM* times the weight of the object

The following is the motor parameter table

Sincere reminder

Your project load should not exceed load rated torque of the motor, otherwise the life of the motor will be reduced or burned

The following introduces the meaning of parameter table ① to (A)

① Reduction ratio

② Input rated DC voltage

③ No-load speed, the unit is RPM/MIN

④ No-load current, unit is A

⑤ Rated load speed, the unit is RPM/MIN

⑥ Rated load torque, unit is kgf.cm.Your project load should not exceed load rated torque of the motor, otherwise the life of the motor will be reduced or motor burned

⑦ Rated input power, the unit is W

⑧ Maximum limit load current, unit is A

⑨ Maximum limit load power, unit is W

⑩ "L" Gearbox length; The length of the gearbox is abbreviated as "L", and the unit of length is mm. This refers to the length of the gearbox corresponding to the parameter you selected. As we all know, the speed of the motor is different, the structure of the gear inside the gear box is different, so the length of the reduction box is different.

Important reminder, the length of the reducer is different, and the total length of the motor is also different. After you have selected the voltage and no-load speed of the motor, you need to check the corresponding length of the gearbox, and then you can refer to the size diagram below to get the motor total length.

(A) Approximate net weight of the motor, the unit is (g)

The following is the dimension drawing of the motor

Important reminder

Because we use different measuring tools, so the measurement data of the product size will be slightly different.

If your project has high requirements for the size of the motor, we recommend that you contact us before purchasing.Thank you very much!

We named the length of the gearbox as L. Please note that the length of the gearbox varies with the speed of the motor. Please refer to the length of L in the parameter table for details.

The length of the gearbox is about 23mm to 40mm. The length of the gearbox is different for different speeds, so please check the corresponding gearbox length in the parameter table according to the speed you choose.

The following are some pictures of the product

Care Instructions

Care Instructions